15. 1. 2018

In every soil conditions

Vibromulch range has been completely reworked with new mounted and trailed versions! for mounted version and 6-8 meters for trailed version in order to always provide more efficiency and high Vibromulch, is the range of vibrating tines cultivators since 2010. For 2017, the range is completely reworked to adapt itself to a wide range of operations, from light stubble-breaking to after ploughing work up to seedbed preparation. The range will be available in 4-5-6 meters working rate for all kind of farms.

Profits at all levels

Either in 4 rows for the mounted version, or in 5 rows for the trailed version, the Vibromulch with its 16.6cm interval between the tines and its under beam height of 60 cm offers the largest clearance on the market. Regardless of the type of crop residues, the design of the machine ensures homogenous work over the entire working width to avoid all clogging risks.

2017 Vibromulch version: two configurations available!

- First serial configuration with vibrating tines of 70x12mm equipped with straigt shares or sweep shares of 180mm. This configuration enables an intensive work on soil surface, either as second stubble-breaking or for tillage after ploughing, ensuring a good ventilation and warming up of the seedbed.

- An optional configuration with 30x30 mm 3D security tines offers high resistance and enhanced percusssion power. Associated with straigt shares, these tines are adapted to agressive work which provides a good soil-straw mixture at first stubble-breaking. Mounting sweep shares on that tine makes it more versatile for light soil work.

A wide range of options available to complement tines work!

Before working with the tines implement several options can be added on the machine:

- Coulters discs which ensure the first soil opening and the first vertical cut of crop residues facilitating a good soil penetration of the tines

- One row of front cross-board which allow a good soil levelling before passing with the tines

Then after tines pass, different solutions are available to make the machine extremely versatile:

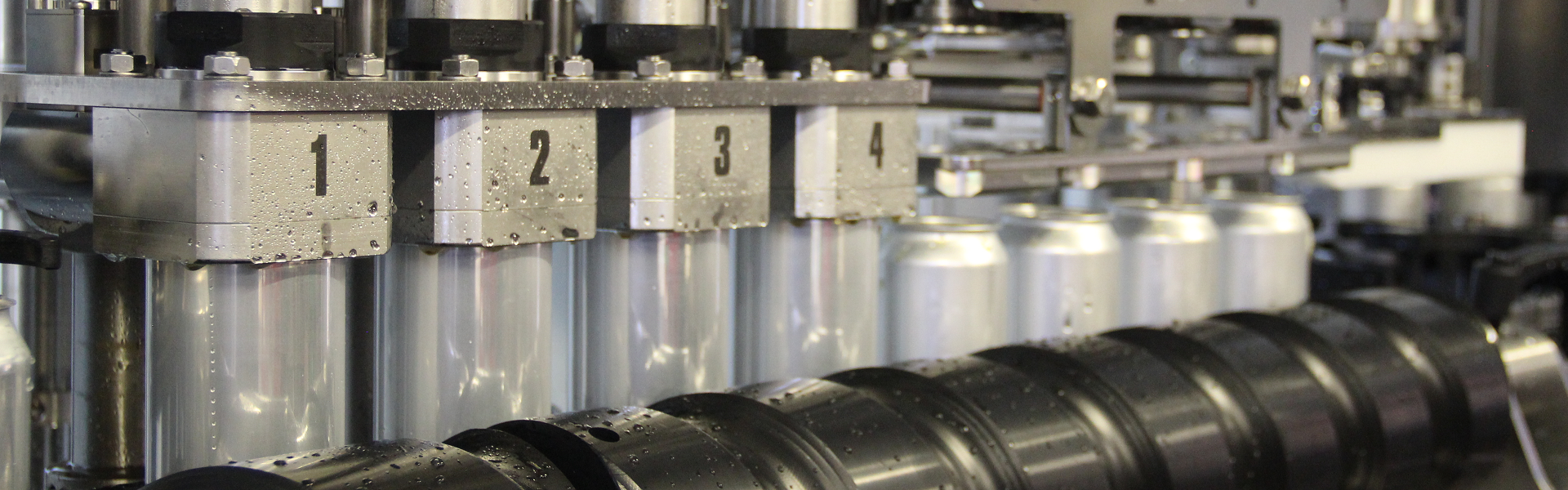

- A wide selection of rollers relevant to different types of soils and working conditions. (Click here to see the different rollers)

- A 3 rows harrow instead of the roller allows performing a “crude” levelling.

- Moreover, covering harrows are available as an option before/after roller, dedicated for heavy soils in order to achieve excellent crumbling and refined seedbed

Finally, in order to complete the machine, depth control wheels are positioned at the front and at the rear. The machine can therefore be used without roller while maintaining an optimal adaptation to every soil variation whatever the working conditions.