2. 12. 2016

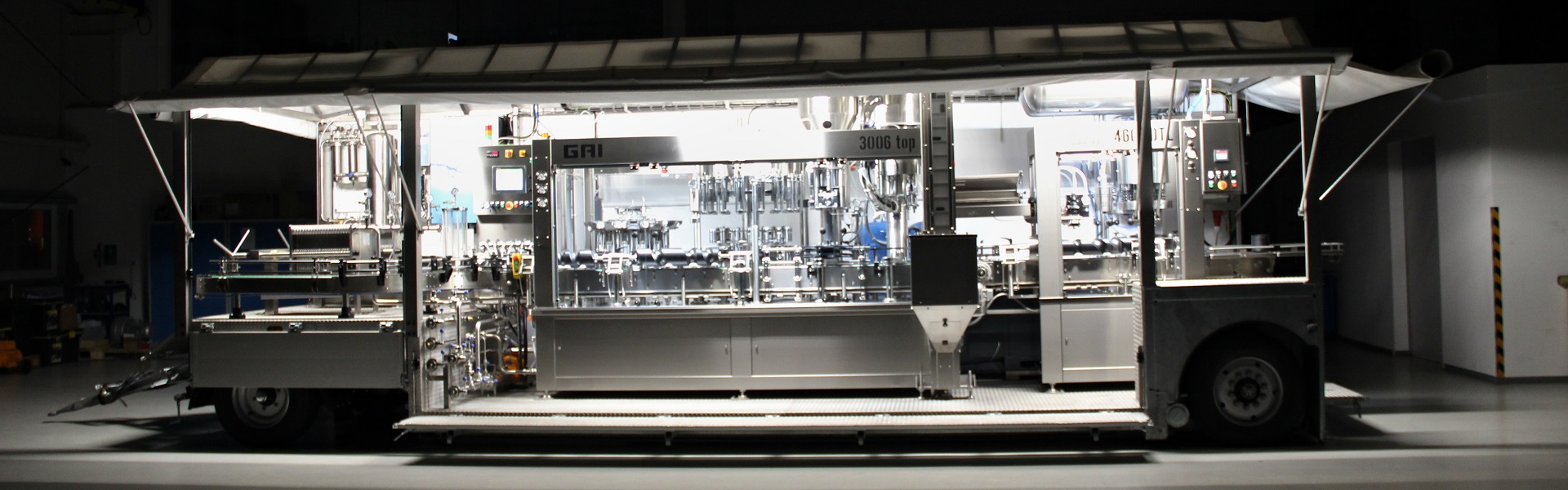

AutoSelect

HARDI introduces an air-driven nozzle concept, where the sprayer driver can change between 2 nozzles or use both at the same time. You can use one type of drift reducing nozzle at the headland or at sensitive buffer zones and a “conventional” flat fan nozzle or low drift nozzle in the field. The sprayer driver may also consider the wind conditions and change nozzle if it blows more than when the nozzle was chosen at the start of spraying.

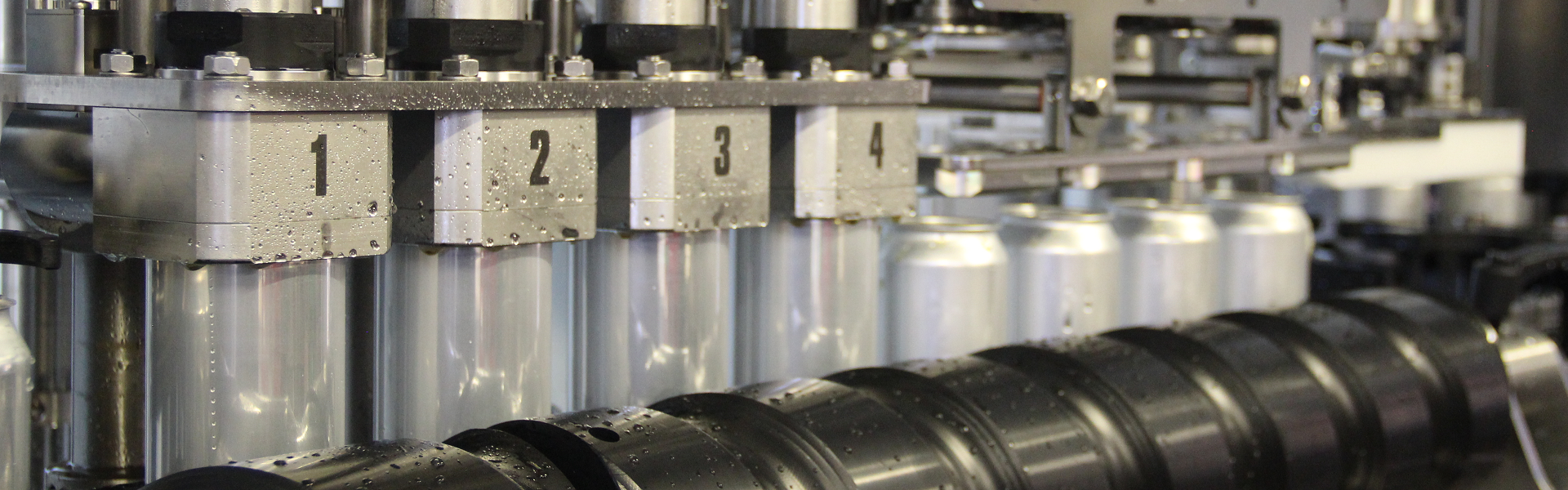

Change between 4 different functions can take place:

- Spraying with nozzle A

- Spraying with nozzle B

- Spraying with both nozzle A+ B

- Auto mode – here AutoSelect can work with a pre-defined spraying pressure or pre-defined working speed

Good at changes of speed

If very big changes of the speed are needed, AutoSelect can automatically and quickly change between two nozzle sizes so the work of the individual nozzle is taken over by a bigger nozzle at increased speed and does not have to work in the outer areas for pressure or flow. This gives a better spray quality and a better application.

Changes of dosage during spraying

If you have to change the dosage in the field, this can be done by changing to a more suitable nozzle “on the go” without compromising on quality. AutoSelect is very identical with the set-up of the PrimeFlow which HARDI has so far offered the market and is not a replacement for PrimeFlow. 9 or 13 sections are possible. AutoSelect works with air pressure, and if you have a pneumatic braking system on your tractor, the air pressure source is secured.