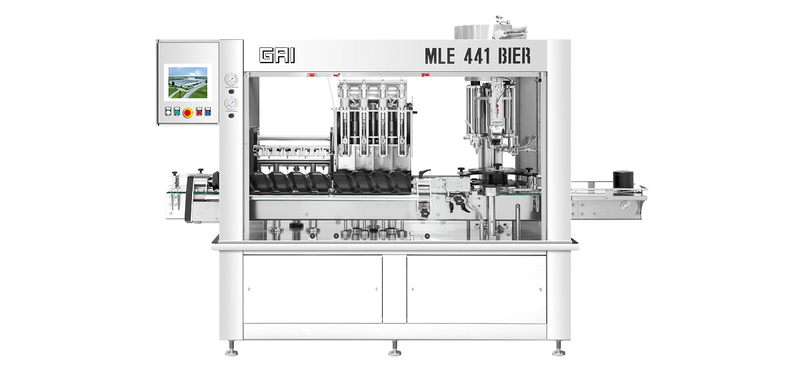

Filling machines GAI MLE BIER

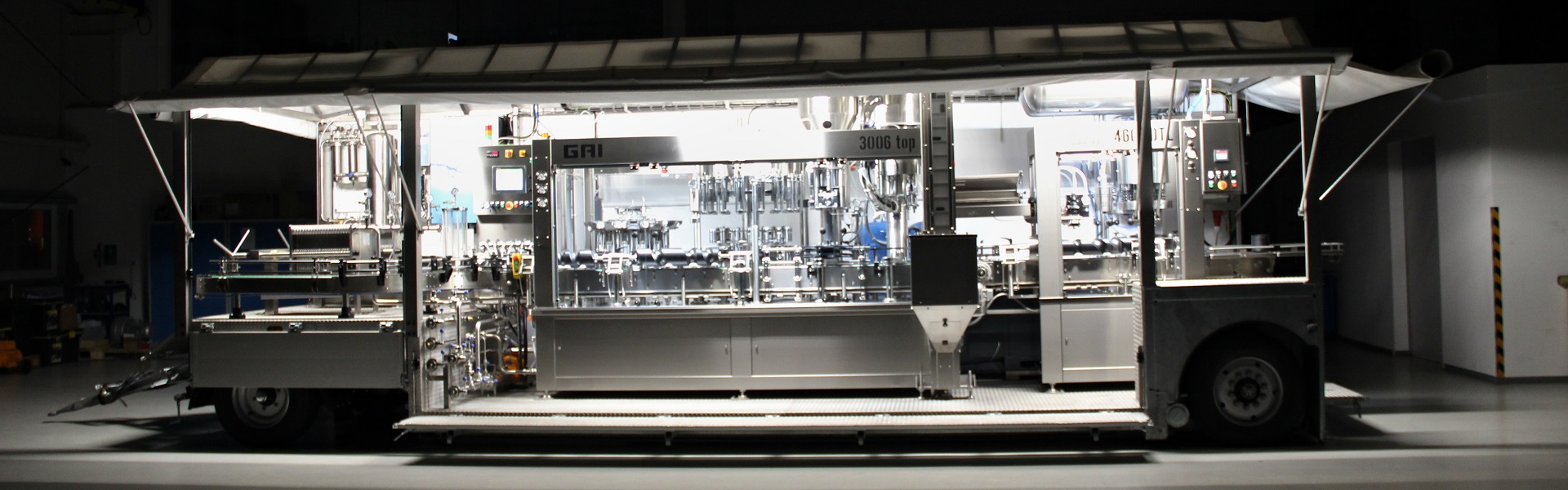

Linear filling machines series MLE BIER includes different functions: rinsing, complete filling cycle with electro-pneumatic valves and the possibility of closing up to 3 types of closures at one station.

The MLE BIER series has been designed to meet the needs of even smaller production while ensuring all the benefits of electropneumatic filling at an affordable price. These machines are simplified versions of larger and more powerful fillers, thus guaranteeing flexibility, performance and quality.

1. RINSING

Electropneumatic LINEAR rinser in stainless steel for bottles with max diameter of 115mm. The bottles are taken on the neck by a universal "floating" pincer and turned upside-down through a chain system with step-step motor. The nozzle enters the bottle neck for 70mm. The injection duration may be adjusted from the control panel and the injection takes place only if the bottle is present. There is no contact between the bottle and the injector. The dripping liquid is collected in a close circuit without wetting the machine.

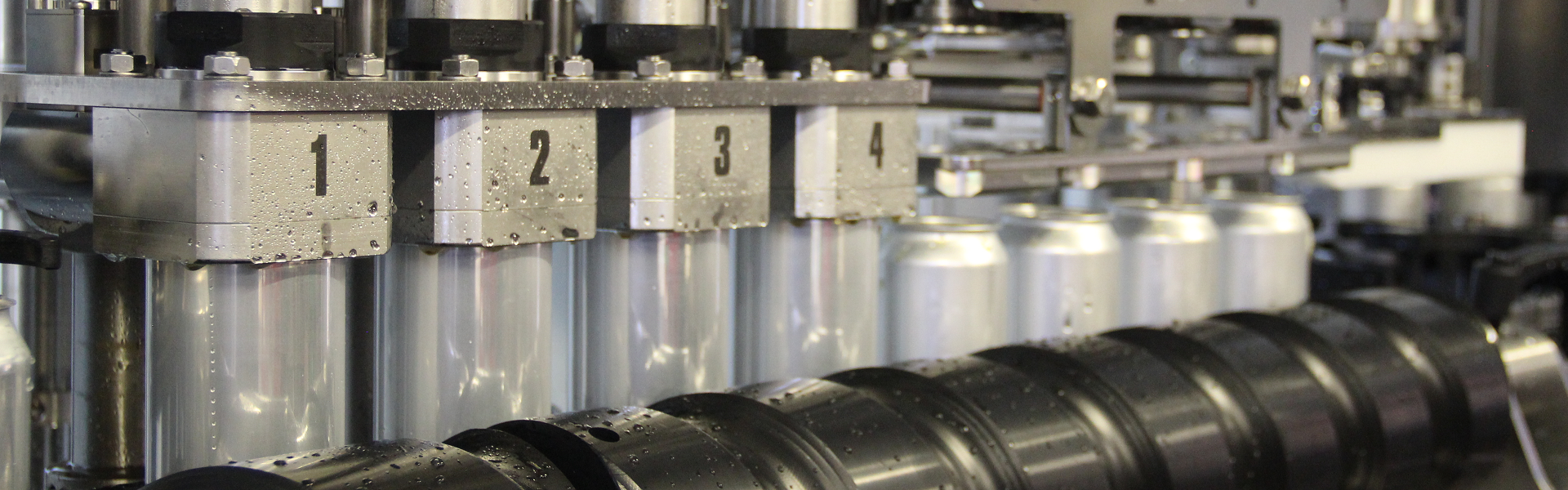

2. HIGH PRESSURE LINEAR electropneumatic filler for bottles with 115mm max diameter.

Each valve includes:

- Bottle presence sensor.

- Pressure transducer to control the vacuum and the pressure in bottle (the valve does not start filling if the bottle does not reach the tank pressure)

- Electropneumatic valve for vacuum circuit

- Electropneumatic valve for the auto-levelling circuit and pressure compensation

- Electropneumatic valve for de-gassing circuit.

- Electropneumatic valve on each spout, to allow, if the bottle is present, the vacuum, the pressure compensation, the autolevelling and the de-gassing.

- Double effect electropneumatic piston on each valve for gas returning circle opening and closing.

- Double effect electropneumatic piston on each valve to liquid circuit opening and closing.

- The filling level is centralized and can be adjusted manually from 25 to 100mm from the mouth. The bottle neck internal Ø must be higher or equal to 16mm. Each valve has dummy bottle with manual positioning for machine washing and sterilization.

- The valve can work both with gassed liquids with pressure up to 8 bar and with still liquids with pressure up to 0 bar. The filling level is precise even without the use of the auto-levelling circuit. The total closing of the filling valve helps the degassing even with difficult products and allows the bottling of sparkling liquids even at environment temperature.

- The filling level is protected by patent n° TO2012A000869

- All circuits are canalized (even the degassing one) and the filler is set for a sterilization CIP system. The feeding from the bottom allows a natural and total emptying of the tank. The flow is adjusted by an electropneumatic valve. Bottle double pre-evacuation: the air in the bottle is sucked and replaced with CO2 in pressure, it is sucked again before balancing the bottle pressure with the tank one. In this way 99% of oxygen in bottle is eliminated. The vacuum is created by a liquid ring pump. The gas pressure in tank and the levelling circuit one are managed by PLC.

3. WATER JET

Water jet that creates beer foam in the bottle neck immediately before crown capping. The use of an electropneumatic valve allows adjusting the jet duration directly from the control panel.

4. CROWN CAPPING

Single head 4270 crown capping fed by vibration.

The inlet and transfer among the stations takes place with an universal infeed screw that guides and synchronize the bottles. Electrical height adjustment of all stations. The working in line is designed only in siding. Equipped for a cylindrical bottle.

The monobloc is equipped with:

- Safety guards in accordance with CE standards with tempered glass doors.

- Universal infeed screws.

- Dummy bottle for rinser sterilization

- Dummy bottle for filler sterilization

- Dummy bottle for foam jet sterilization

- PLC and operating terminal (touch screen).

- Cork/capsule presence device.

| FUNCTIONS | MLE 441 BIER | MLE 661 BIER | MLE 881 BIER | |

| Rinsing | n. | 4 | 6 | 8 |

| Filling | n. | 4 | 6 | 8 |

| Capping | n. | 1 | 1 | 1 |

| Production speed | bottles/hour | up to 900 | up to 1.200 | up to 1.500 |

| Output | litres/hour | 375 | 525 | 675 |